The Definitive Buyer's Guide to Particle Counters: Navigating Technology, Compliance, and Smart Procurement

In today's precision-driven industries, from semiconductor fabrication to biopharmaceutical production, controlling particulate contamination is not just a best practice—it's a critical component of product quality, safety, and regulatory compliance. Selecting the right particle counter is a complex decision that impacts operational efficiency, capital expenditure, and long-term viability. This comprehensive buyer's guide, crafted with insights from Zetron's nearly two decades of expertise in industrial detection, will walk you through the essential considerations, technical nuances, and strategic questions to ask before making your investment.

Zetron's B330/B550/B1030 series exemplifies modern multi-channel monitoring for comprehensive environmental analysis.

Chapter 1: Understanding Your Core Application & Particle Type

The first and most crucial step is defining what you need to measure. The choice between an air particle counter, a liquid particle counter, or a hybrid system dictates the entire technology path.

Key Questions to Ask:

- Media: Are you monitoring cleanroom air (particle counter clean room), process water (ultrapure water in semiconductors), hydraulic fluids, or injectable pharmaceuticals?

- Environment: Is it a controlled GMP particle counter environment, a harsh industrial setting, or a field-based environmental particle counter application?

- Particle Source: Is the concern from general dust particle counter activities, specific process-generated aerosols (aerosol particle counter), or biological contaminants?

For instance, a pharmaceutical particle counter for aseptic filling lines must comply with EU GMP Annex 1 and FDA guidelines, often requiring a laser particle counter with high sensitivity for 0.5µm and 5.0µm sizes. In contrast, an HVAC particle counter for building management might prioritize broader size ranges and network connectivity.

Chapter 2: Critical Technical Specifications Demystified

Beyond the basic type, dive into the specs that define performance. Don't just compare numbers; understand what they mean for your operation.

| Specification | What It Means | Buyer's Consideration |

|---|---|---|

| Flow Rate | Volume of air/liquid sampled per minute (e.g., 1 CFM, 2.83 L/min, 28.3 L/min). | Higher flow rates (like 28.3 L/min) sample more volume faster, providing better statistical significance for low contamination levels but may be bulkier. A portable particle counter often uses 2.83 L/min for balance. |

| Channel/Size Bins | Number of particle size ranges the counter can differentiate (e.g., 0.3, 0.5, 1.0, 5.0 µm). | More channels (like Zetron's 6-channel counters) provide richer data for trend analysis and root cause investigation. Match channels to your cleanroom class or product specification limits. |

| Detection Technology | Typically optical particle counter or laser diode-based (laser particle counter). | Laser-based offers superior accuracy, especially at smaller sizes (sub-micron). Zetron's breakthrough in submicron detection technology is key for advanced semiconductor nodes. |

| Counting Efficiency & Resolution | Ability to accurately detect particles at a given size threshold (e.g., 50% at 0.1µm, 100% at 0.2µm). | Verify against standards like JIS B9921 or ISO 21501-4. Higher efficiency reduces false negatives. |

The Rise of Real-Time and Connected Systems

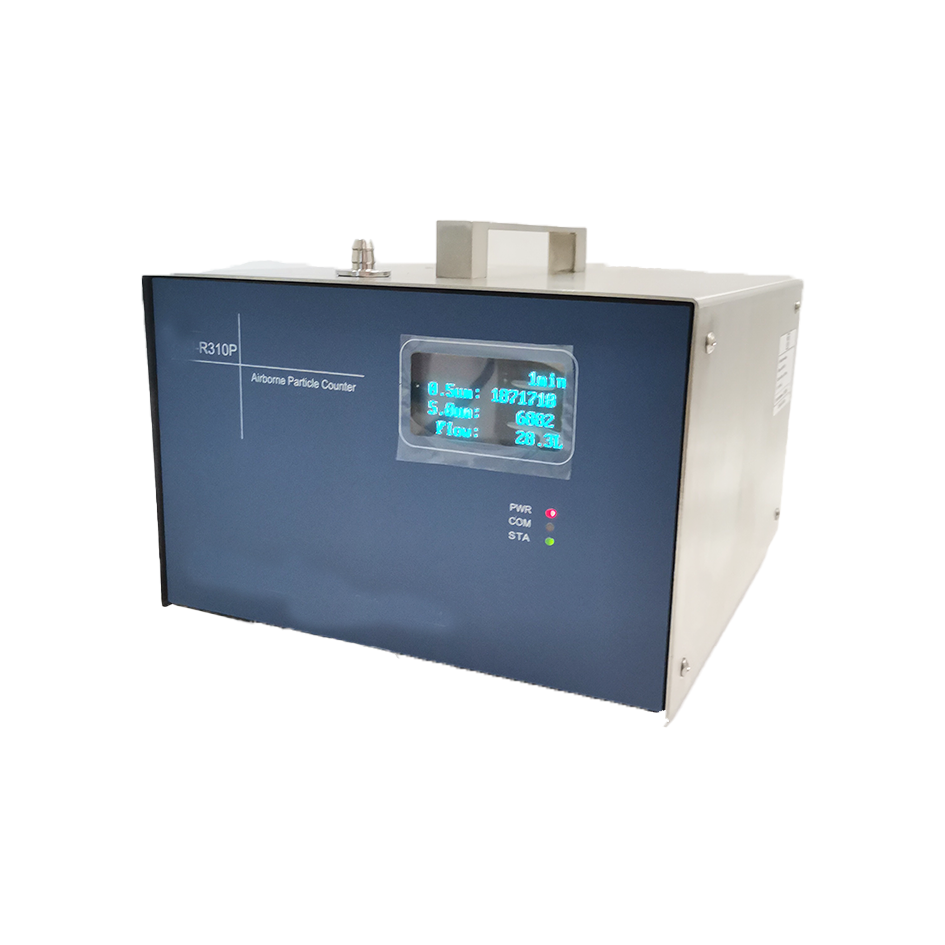

A major trend is the shift from periodic manual checks to continuous, real time particle counter systems. An online particle counter like Zetron's R210 or R310P series provides constant data streams, enabling immediate alarm response and process control integration. For industrial particle counter applications, this connectivity via IoT platforms is transforming quality assurance from a quality control (QC) function to a quality assurance (QA) pillar.

Zetron R310P: An online particle counter designed for permanent installation and system integration.

Chapter 3: Form Factor & Operational Needs

Where and how will the instrument be used? This determines the physical design.

- Handheld Particle Counter: Ideal for spot checks, mapping cleanrooms, and audit trails. Look for lightweight design, long battery life, and intuitive interface. Zetron's B110-Pro is a prime example.

- Portable Particle Counter: Often larger than handhelds, with more features (built-in printer, more channels) but still movable for validation studies in different locations.

- Fixed/Benchtop/Online Systems: Permanently installed for continuous monitoring of critical locations (laminar flow hoods, filling lines, HVAC particle counter ducts). Prioritize robust communication protocols (Modbus, Ethernet, 4G) and compatibility with your SCADA or BMS.

Chapter 4: Compliance, Calibration & Total Cost of Ownership (TCO)

Your particle counter for laboratory or production must be more than just accurate; it must be defensibly accurate in an audit.

The Zetron Assurance: Certifications Matter

As a one-stop industrial testing equipment solution provider, Zetron's commitment to quality is validated by a suite of international certifications. These are not just badges; they are your guarantee of reliability and global acceptability:

ISO9001 QMS

ISO45001 OHS

ISO14001 EMS

ATEX (Explosive Atmospheres)

Furthermore, Zetron instruments are designed to meet ISO14644 cleanroom standards, EU GMP, and FDA CFR 21 part 11 (for data integrity), making them a trusted choice for regulated industries.

Calibration: Factor in the cost and downtime for annual calibration. Does the supplier offer traceable calibration services? Zetron provides full-chain support, ensuring your equipment maintains its accuracy over time.

TCO: Consider purchase price, calibration costs, maintenance, consumables (sensors, filters), software licenses, and training. A slightly higher upfront cost for a more reliable, feature-rich digital particle counter from a reputable maker like Zetron often results in lower TCO through fewer failures, less downtime, and longer service life.

Chapter 5: The Zetron Advantage - Beyond the Hardware

Choosing Zetron means partnering with an expert. With nearly 20 years in detection technology, we offer more than just devices:

- Application Expertise: From semiconductor fabs to biopharmaceutical cleanrooms and environmental monitoring stations, we understand your unique challenges.

- Customized Solutions (OEM/ODM): Need a specific form factor, communication protocol, or software integration? Our full-chain OEM/ODM services adapt our core technology to your exact workflow.

- Integrated Systems: We provide complete monitoring systems, combining airborne particle counters, sensors, and our environmental safety monitoring cloud platform for a unified view.

- Global Support: Trusted by clients like Donaldson and Samsung, our technical support spans from needs diagnosis to installation and maintenance.

Precision manufacturing and rigorous testing at Zetron's facilities ensure every particle counter delivers reliable performance.

Your Procurement Checklist

Before finalizing your purchase of a particle counter, use this final checklist:

- ✅ Have I clearly defined the application (air/liquid, cleanroom/industrial)?

- ✅ Do the technical specs (flow rate, channels, sensitivity) match my standards (ISO, GMP)?

- ✅ Is the form factor (handheld, portable, online) suitable for my intended use?

- ✅ Does the supplier offer necessary certifications (CE, ISO, GMP-compliant data output)?

- ✅ What is the calibration process, cost, and recommended interval?

- ✅ Can the device integrate with my existing systems (IoT, BMS, SCADA)?

- ✅ What is the supplier's reputation, after-sales service, and technical support capability?

For a detailed consultation on selecting the ideal particle counter for your semiconductor, pharmaceutical, or environmental application, contact the Zetron team today.

Beijing Zetron Technology Co., Ltd.

Website: www.zetroncn.com | Email: info@bjzetron.com | Tel: +86-15699785629

One-stop industrial testing equipment solution provider.