A Step-by-Step Guide to Particle Counter Selection and Deployment

In today's precision-driven industries, from semiconductor fabrication to biopharmaceutical production, maintaining a controlled environment is non-negotiable. The core of this control lies in accurate and reliable particle monitoring. Selecting the right particle counter is not just a purchase; it's a critical operational decision. This guide, drawing from Zetron's nearly two decades of expertise in industrial testing, will walk you through the process of choosing and implementing the perfect particle monitoring solution for your specific cleanroom needs.

Why This Guide Matters Now

Recent industry dynamics, including stricter revisions to EU GMP Annex 1 and the relentless drive for miniaturization in semiconductor nodes, have placed unprecedented emphasis on sub-micron particle control. A generic airborne particle counter is no longer sufficient. You need a strategy.

Step 1: Define Your Application and Critical Parameters

Before looking at models, define your battlefield. The type of particle counter you need is dictated by your application.

- For ISO Class 5 (Class 100) cleanrooms in Pharma: You'll need a high-sensitivity laser particle counter capable of detecting particles down to 0.5µm and 5.0µm, compliant with EU GMP and FDA CFR 21 Part 11 for data integrity. A pharmaceutical particle counter like Zetron's H630 series is designed for this.

- For Semiconductor Fabs: Monitoring air and ultrapure water (UPW) is crucial. You'll likely need both an air particle counter for the cleanroom and a liquid particle counter for point-of-use water monitoring. Look for counters that meet SEMI standards.

- For HVAC System Balancing & Environmental Monitoring: A robust, portable particle counter or a fixed online particle counter integrated into your Building Management System (BMS) is key. Devices like Zetron's R210 or R310P are built for continuous environmental particle counter duty.

- For Spot Checks and Field Service: A handheld particle counter offers mobility. For broader area surveys, a portable particle counter with a longer battery life and data logging is essential.

Zetron's H630 Particle Analyzer: Designed for precision monitoring in GMP-critical environments like biopharmaceutical cleanrooms.

Zetron's H630 Particle Analyzer: Designed for precision monitoring in GMP-critical environments like biopharmaceutical cleanrooms.

Step 2: Understand the Technology & Key Features

Not all optical particle counter technologies are equal. Most modern devices use light scattering (laser or LED). Here's what to scrutinize:

- Flow Rate & Sampling Time: Standard flow rates are 1.0 CFM (28.3 L/min), 0.1 CFM (2.83 L/min), or 50 L/min for larger volumes. Higher flow rates sample more air, yielding statistically significant data faster, which is vital for real time particle counter applications in dynamic environments.

- Particle Size Channels & Resolution: Can it distinguish between 0.3µm, 0.5µm, and 5.0µm? More channels provide finer data for trend analysis. Zetron's digital particle counter platforms often feature 6+ user-configurable channels.

- Data Integrity & Compliance: For GMP particle counter applications, features like audit trails, user access levels, electronic signatures, and 21 CFR Part 11-compliant software are mandatory. Ensure your supplier understands these requirements.

- Connectivity & IoT Readiness: Can the industrial particle counter connect via Ethernet, Wi-Fi, or Modbus? Devices like Zetron's R310P online particle sensor are built for seamless integration into plant-wide monitoring networks and cloud platforms.

- Calibration & Certification: Verify the calibration standard (e.g., NIST-traceable) and the availability of routine calibration services. Zetron's devices are calibrated using internationally recognized protocols.

Step 3: Develop a Strategic Monitoring Plan

Your particle counter for laboratory or production cleanroom is only as good as your plan. Follow ISO 14644-1 and -2 guidelines for particle counting.

- Locations: Identify critical zones (at rest & in operation), including the product exposure point, equipment interfaces, and room background.

- Frequency: Continuous monitoring for Grade A zones, periodic for Grade B/C. Use online particle counter networks for continuous data.

- Alert and Action Levels: Set limits based on your cleanroom classification. Your aerosol particle counter should have programmable alarms for immediate notification.

- Documentation: Every reading must be documented. Choose counters with built-in printers or direct data export to PDF/Excel.

Professional testing and calibration are integral to Zetron's service, ensuring every particle counter delivers reliable data.

Professional testing and calibration are integral to Zetron's service, ensuring every particle counter delivers reliable data.

Step 4: Implementation, Training, and Ongoing Support

Deployment is more than plug-and-play. Partner with a provider that offers comprehensive support.

Beijing Zetron Technology Co., Ltd. exemplifies this approach. As a one-stop industrial testing equipment solution provider, Zetron doesn't just sell a dust particle counter or an HVAC particle counter; they provide a solution.

- Installation & Commissioning: Their team can assist with setting up single units or complex multi-point online particle counter networks.

- Operator Training: Proper use of a handheld particle counter or a complex system is crucial. Zetron provides operational training.

- Preventive Maintenance & Calibration: Regular service ensures long-term accuracy and compliance.

- Data Management: Leverage their environmental safety monitoring cloud platform to centralize data from all your Zetron particle counters and other gas detection devices.

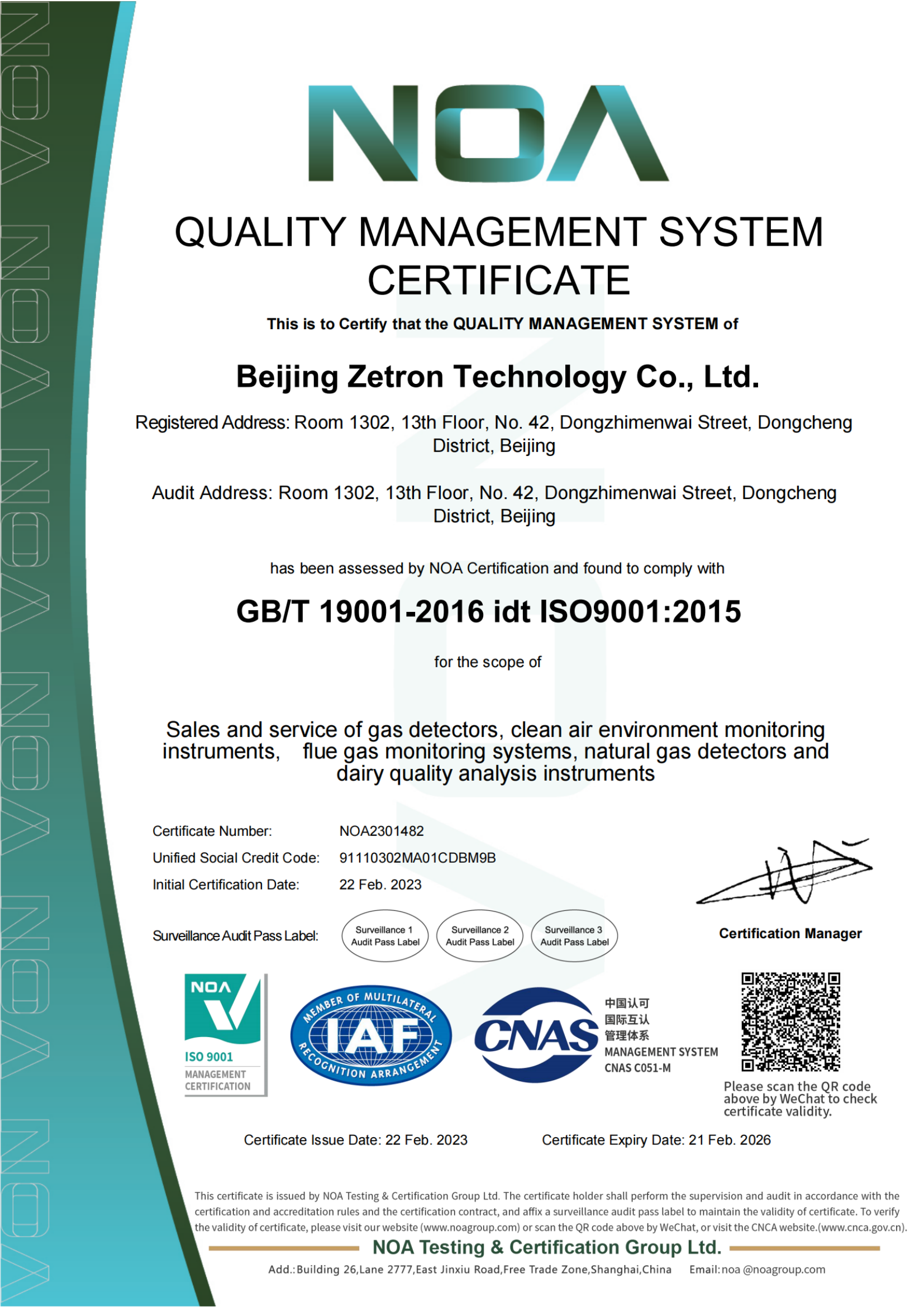

Their commitment to quality is backed by international certifications, including ISO9001:2015 (not 2005 as previously mentioned; standards evolve) for their quality management system, CE, RoHS, and ATEX for use in hazardous areas, ensuring every device meets rigorous safety and performance benchmarks.

Zetron's ISO 9001 and ATEX certifications are testaments to their commitment to quality and safety in manufacturing.

Zetron's ISO 9001 and ATEX certifications are testaments to their commitment to quality and safety in manufacturing.

Conclusion: Building a Foundation of Confidence

Selecting the right particle monitoring system is a technical investment in your product quality and regulatory compliance. By following this structured approach—defining needs, understanding technology, planning strategically, and partnering with an expert provider—you move beyond simply buying a tool to implementing a cornerstone of your quality assurance system.

For nearly 20 years, Zetron has been a trusted partner for global clients like Donaldson and Samsung, providing tailored solutions from a single portable particle counter to a fully integrated, IoT-enabled monitoring grid. Their focus on "leading technology" and "comprehensive monitoring" ensures you have a partner capable of navigating the complexities of modern particle counter clean room requirements.

Ready to Implement Your Particle Monitoring Strategy?

Contact the Zetron team today for a personalized consultation. Discuss your application in semiconductor, lithium battery, biopharmaceutical, or environmental monitoring, and explore their full range of air particle counters, liquid particle counters, and integrated systems.

Beijing Zetron Technology Co., Ltd.

Website: www.zetroncn.com

Email: info@bjzetron.com

Tel: +86-15699785629

Address: 19B, Office Tower, Oriental Ginza, No.48 Dongzhimenwai Street, Dongcheng District, Beijing, China.